2nd Generation Twister Bearing Technologie

Patented Twister Bearing Technology

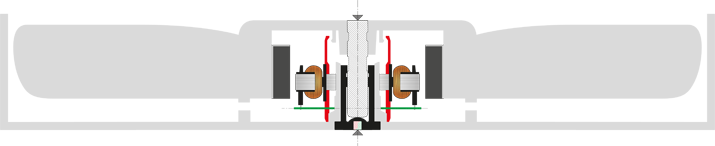

The bearing shaft is fixed to the rotor. When you turn the fan on, a small magnet inside the bearing holds the shaft in position. The convex surface of the base reduces the frictional resistance and ensures a quiet and smooth fan rotation. The sleeve is made from a self-lubricating material and prevents the bearing from draining and corrosion. That way, Enermax guarantees an exceptionally long lifetime of 160,000 hours (MTBF). Another useful feature of the Twister fans is the “Click Mechanism”. By pressing the rear side of the blades, you can detach the rotor and clean it from dust. Put it back on the base and press it down until you hear a “click”.

>> Watch a video about the Twister Bearing Technology